Drum speed is an important but frequently overlooked factor in coffee roasting. The rotation of the drum determines the way coffee beans move within the roaster, which affects the roast in two important ways. Firstly, drum rotation is essential to mix the beans and ensure an even roast. Secondly, more importantly, the drum speed determines the amount of contact the beans have with the roasting gases and the drum wall, and it therefore has a big effect on heat transfer during the roast.

If the beans spend too much time in contact with the drum wall in a directly heated roaster, their surfaces may burn. Further, because beans touching the drum wall have limited contact with roasting gases, they miss out on convective heat transfer. Convection provides most of the heat needed to fully develop the beans. Controlling the drum speed therefore allows a roaster to prevent roast defects caused by bean-surface burning. By controlling the amount of contact between the beans and the roasting gases, a roaster can manipulate the amount of convective heat transfer.

Flow Regimes

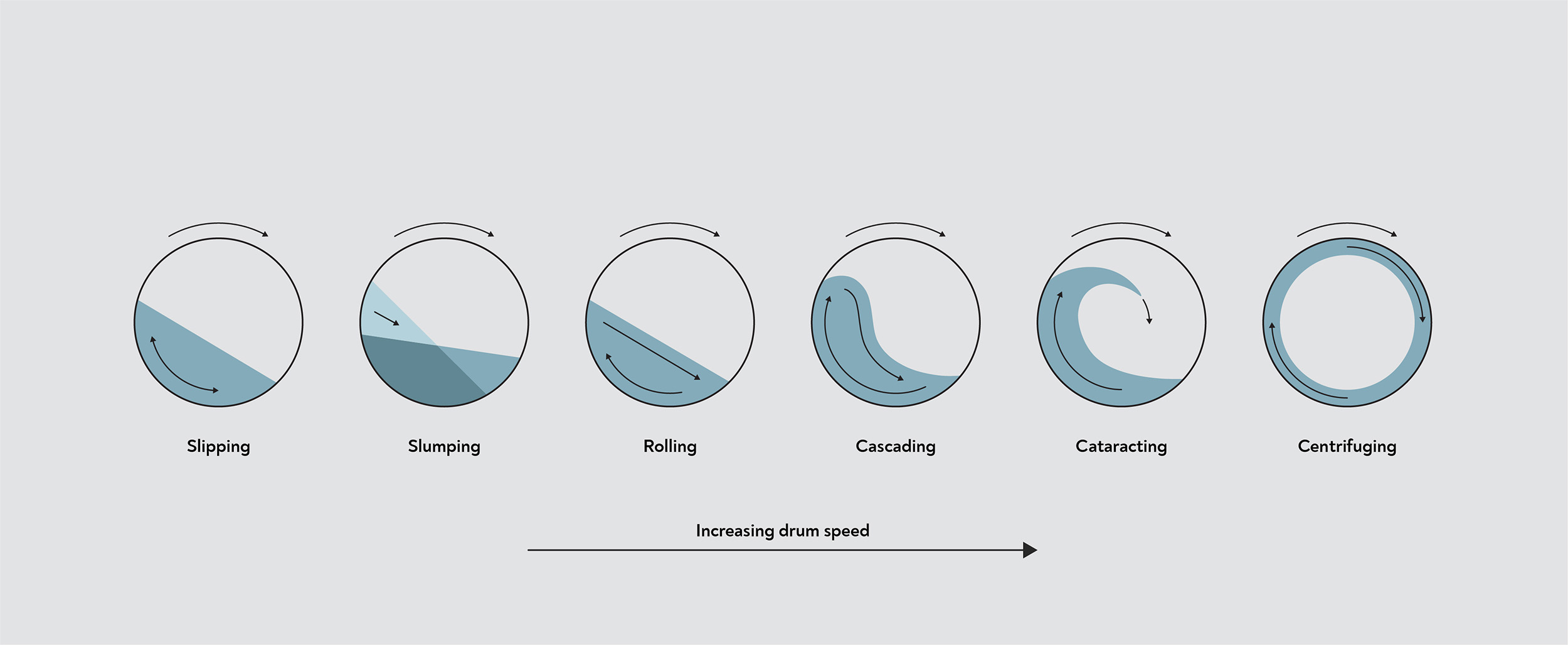

The movement of coffee beans within a rotating drum is described in terms of distinct patterns of motion called ‘flow regimes’. The beans’ flow regime can change when the drum’s rotation speed changes.

Flow regimes of coffee beans in a rotating drum. Adapted from Jones et al 2021

Flow regimes of coffee beans in a rotating drum. Adapted from Jones et al 2021

At very slow drum rotation speeds, the beans move in a ‘slipping’ or ‘slumping’ regime. The bean pile remains in a single mass which moves with the rotation of the drum but then slips or slumps back into position. There is very little mixing of the beans. The beans nearest the drum wall are in contact with the hot drum surface for extended periods of time and therefore likely to burn on their surface.

As the drum rotation speed increases, the beans enter the ‘rolling’ regime. The rotation of the drum pulls beans from the bottom of the bean pile up to one side,