Predicting and controlling the rate of heat transfer to the beans relies on precisely measuring the temperature difference between the beans and their surroundings. Most roasting machines use a type of temperature sensor called a thermocouple to measure the temperature in different parts of the roaster.

Thermocouples ready for installation

Thermocouples ready for installation

A thermocouple consists of two wires made of different materials, and those two wires are joined together at each end. A stainless steel sheath covers the wires and protects the place where the two wires meet (the ‘junction’). The materials used for the wires determine the type of the thermocouple. The J-type and K-type are most common.

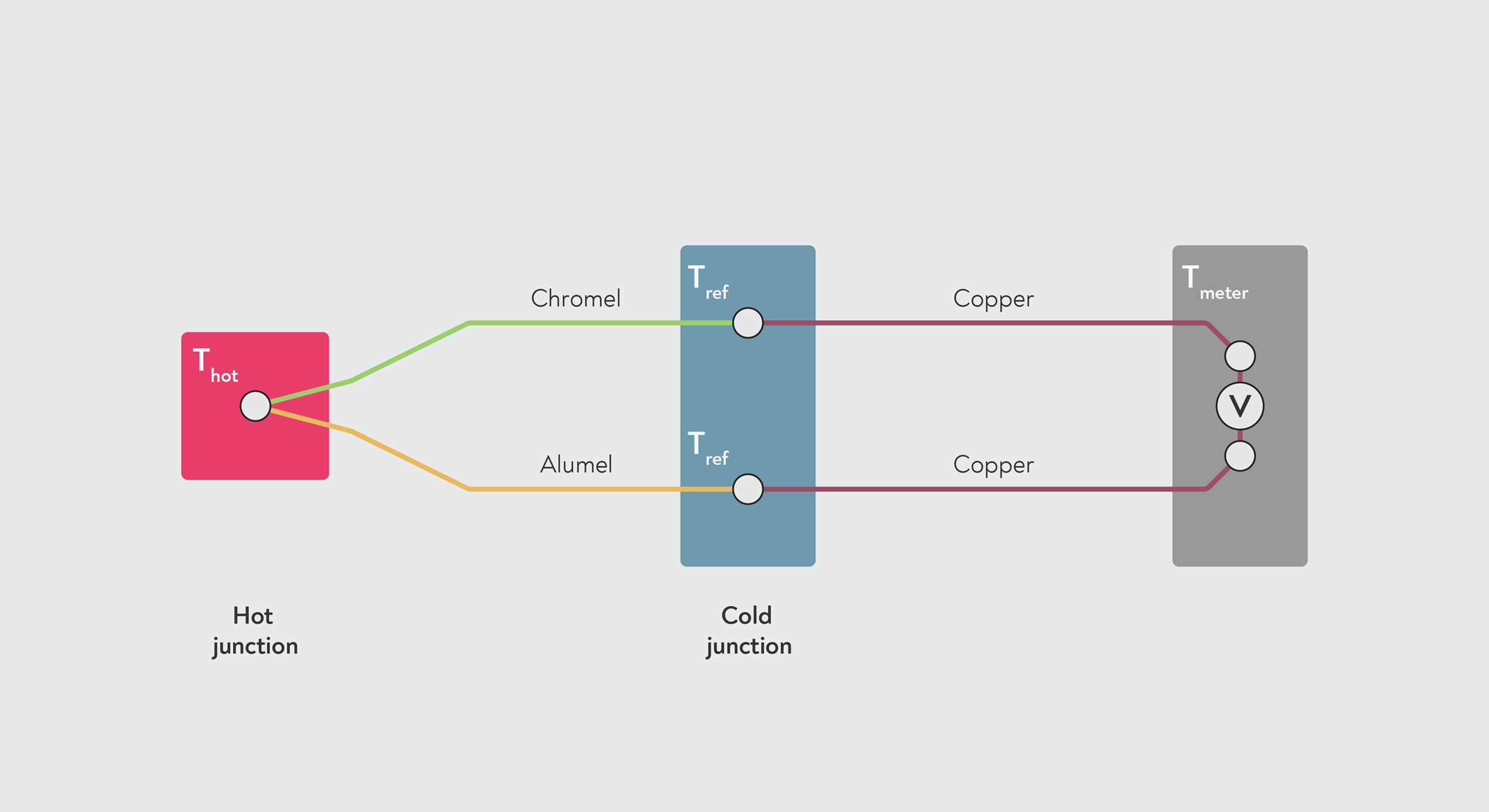

One of the junctions (the ‘hot junction’) between the two wires is located at the tip of the thermocouple, within the part of the machine that will be heated. The other junction (the ‘cold junction’) is positioned outside the roaster, at room temperature. When the hot junction heats up, the temperature difference between the hot and cold junctions generates a tiny electric current. A meter measures the voltage generated and thereby calculates the temperature difference between the hot and cold junctions.

Circuit diagram of a K-type thermocouple — a common type of temperature sensor. The two wires in the thermocouple are made of two different alloys, Chromel and Alumel.The difference between the temperature at the hot junction (Thot) and the temperature at the cold junction (Tref) generates a tiny voltage. The meter connected to the cold junction calculates the temperature difference from the voltage generated.

Circuit diagram of a K-type thermocouple — a common type of temperature sensor. The two wires in the thermocouple are made of two different alloys, Chromel and Alumel.The difference between the temperature at the hot junction (Thot) and the temperature at the cold junction (Tref) generates a tiny voltage. The meter connected to the cold junction calculates the temperature difference from the voltage generated.

The temperature at the cold junction will vary depending on the ambient temperature. Since the meter can only calculate the temperature difference between the two junctions, most thermocouples use a separate temperature sensor to measure the temperature at the cold junction.

When installing a new thermocouple, never trim the wires that connect the probe to the control panel.