by Prof Steven Abbott

The only time I roasted coffee I used a tin can with holes, rotated above an open fire in Kenya. The results were not a great success, but at least the green coffee was fresh and local. I mention this because unlike everyone else who comments on roasting at BH, my views are as a scientist, not a hands-on expert. So feel free to ignore what I say. But sometimes it’s good to have an outsider’s view, as it’s all too common for a community to think that custom and practice are the same as solid truth.

One of my rules as a scientist is to publicly admit and apologize for my errors. So if I’m wrong, you’ll see my apology appear in a future BH post.

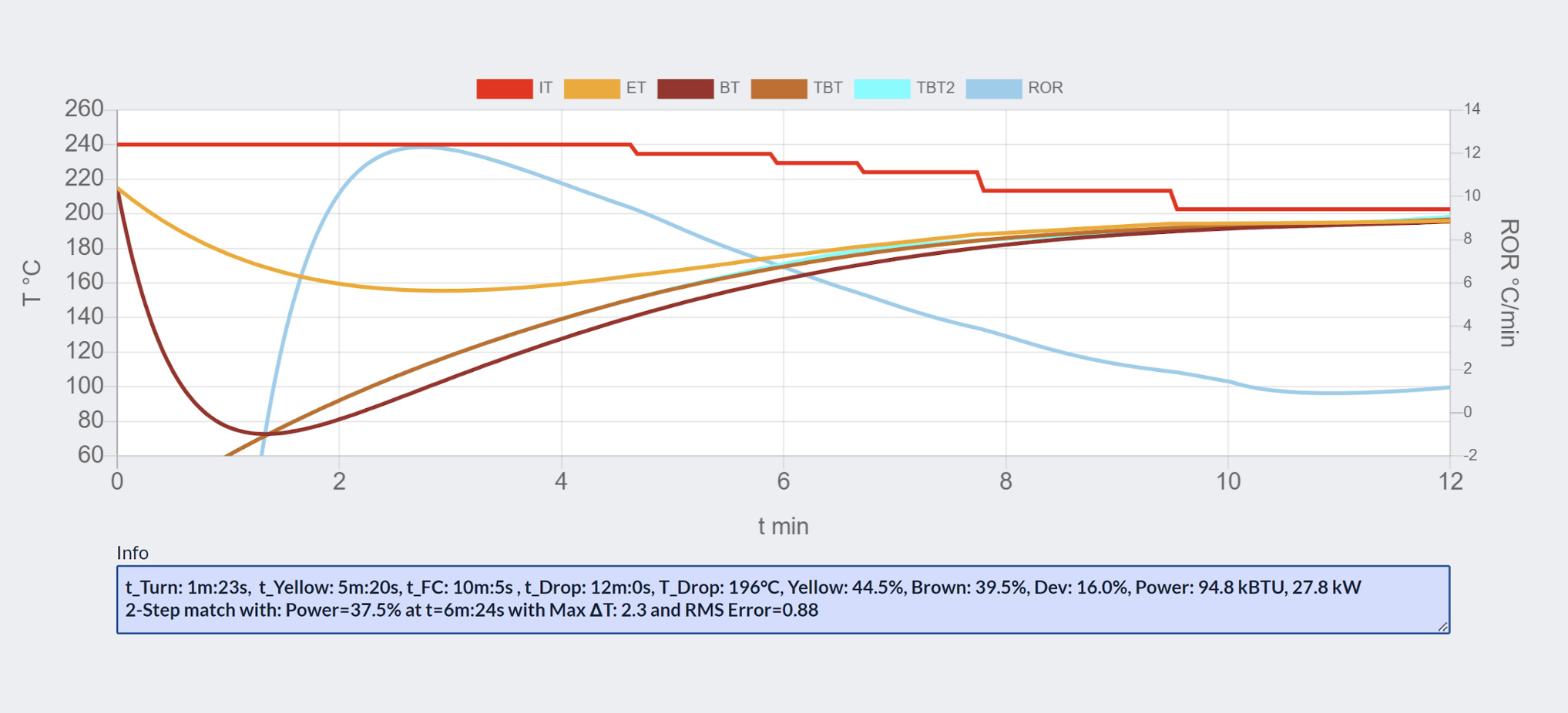

As the title implies, I want to de-emphasise first crack, FC. And while doing so, I want to introduce a new feature I recently added to my coffee roasting app, https://www.stevenabbott.co.uk/practical-mechanical/Coffee-Roasting.php.

The addition takes whatever complex multi-step procedure you have chosen (it’s 6-steps in the screen shot) and automatically finds a 2-step process that best matches the curve of your complex process. 2-step means maximum (reasonable) power at the start, then one step down for the rest of the roast. Although the feature is new, the idea of a 2-step process is not. All I’m doing is alerting the community to a potential simplification of their roasting lives and providing a tool to allow them to experiment on their laptop before committing some real beans to some real experiments.

De-emphasising FC

The common tale is that FC is a major turning point where the water in the green beans explodes, leading to a major expansion of the bean. There are two things wrong with this.

- There are plenty of studies confirming that the majority of the water has left, and the bean has expanded (lower density), before FC, so there isn’t a significant amount of water to explode at that point. After this there is a production of water via chemistry, and this seems to continue indefinitely because the final % water of beans is usually not much different from that at FC.

- Studies have shown (and we know this from the relatively small number of “pops”) that only a small fraction (maybe 15-20%) of the beans participate in FC, so the majority of the beans you have roasted have never cracked – nor could they because they’d already lost most of their water and expanded. I’ve been told that some beans roast perfectly well with no audible crack.

So why is FC so central to all roasting recommendations? Because it’s a convenient signal that provides a reference point in the absence of other clear-cut signals and because the mythology makes it sound so important.

My interpretation, looking at the academic data and also looking at various videos of beans “cracking” is that it’s not a first crack, but a last gasp. Most of the beans have expanded and released their steam. The 15% that pop have done exactly the same expansion but for whatever reason the steam has been trapped a little longer and the extra temperature, or maybe the start of a phase of rapid CO/CO2, is enough to cause that last gasp.

If we de-emphasise FC then we can start focussing on a more significant signal. There’s another reason why de-emphasising FC is important, but we’ll come to that shortly.

A rational signal

We all agree that what happens up to the time around FC is important but not so interesting. The interesting stuff happens when the chemistry starts, producing the various reactions that create the rich panoply of coffee tastes. So wouldn’t it be a good idea to control our roasts by responding to a signal showing that the chemistry has started? This signal is well known and is routinely provided on large commercial roasters as a by-product of their need for a signal that ensures safety in the roaster: it’s the onset of production of carbon monoxide/dioxide, CO/CO2.

Relatively few papers describe the use of this signal, but from those that do, it’s obvious that it’s a more significant signal than the rather arbitrary audible signal of FC or the less direct measure of water vapour with its complex behaviour of removal and creation. My best interpretation of the small amount of relevant data is that there is a modest stream of CO/CO2 coming from the steady Maillard browning in the 10’s of °C before we hear the FC signal, then the stream really takes off as other chemistry takes over. We’d need some dedicated experiments to refine these ideas.

I don’t know why the CO/CO2 signal is not routinely provided on all roasting machines. The sensors cost a few $ and even an amateur can set up an Arduino system to gather the raw signal and produce a meaningful output. As everyone has enough channels on their Cropster/Artisan data systems there is no reason why this isn’t standard practice for monitoring the roast and, at no extra equipment cost, adding a fire safety alert if the level exceeds a danger limit.

0 Comments