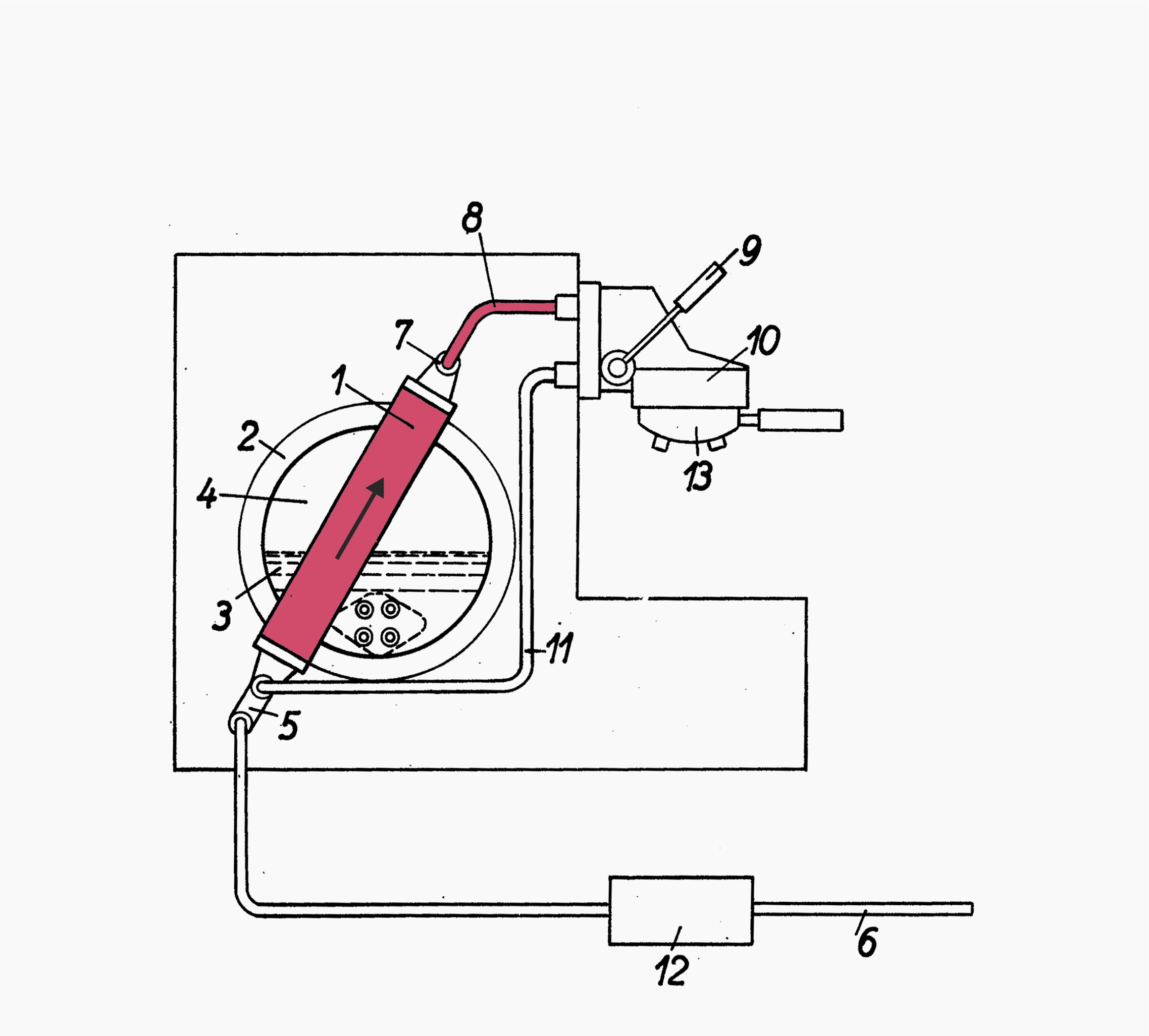

Several features account for the success of Faema’s revolutionary E61 espresso machine. In this lesson, we explain how a thermosyphon works, using an illustration from Ernesto Valente’s 1960 patent.

By constantly cycling hot water through the group, a thermosyphon helps to keep the espresso machine brew temperature stable. It does this by harnessing the power of convection — not by using a pump.

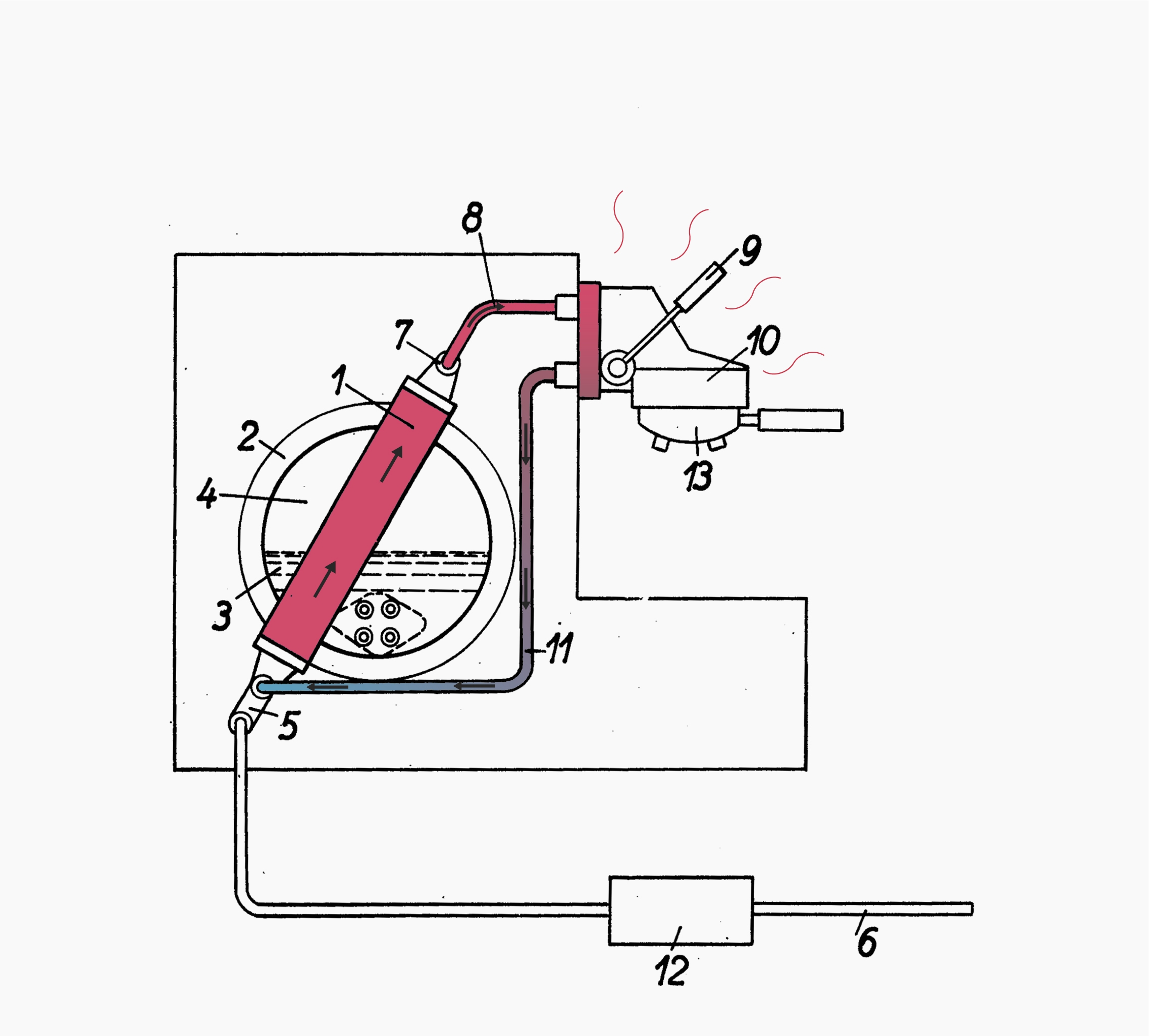

In Valente’s machine, a heat exchanger (1 in the diagram) passes through the middle of the steam boiler. The water inside the heat exchanger is rapidly heated to above 100°C (212°F). Because the hot water is less dense than the cooler water in the group, it rises and flows into the group head.

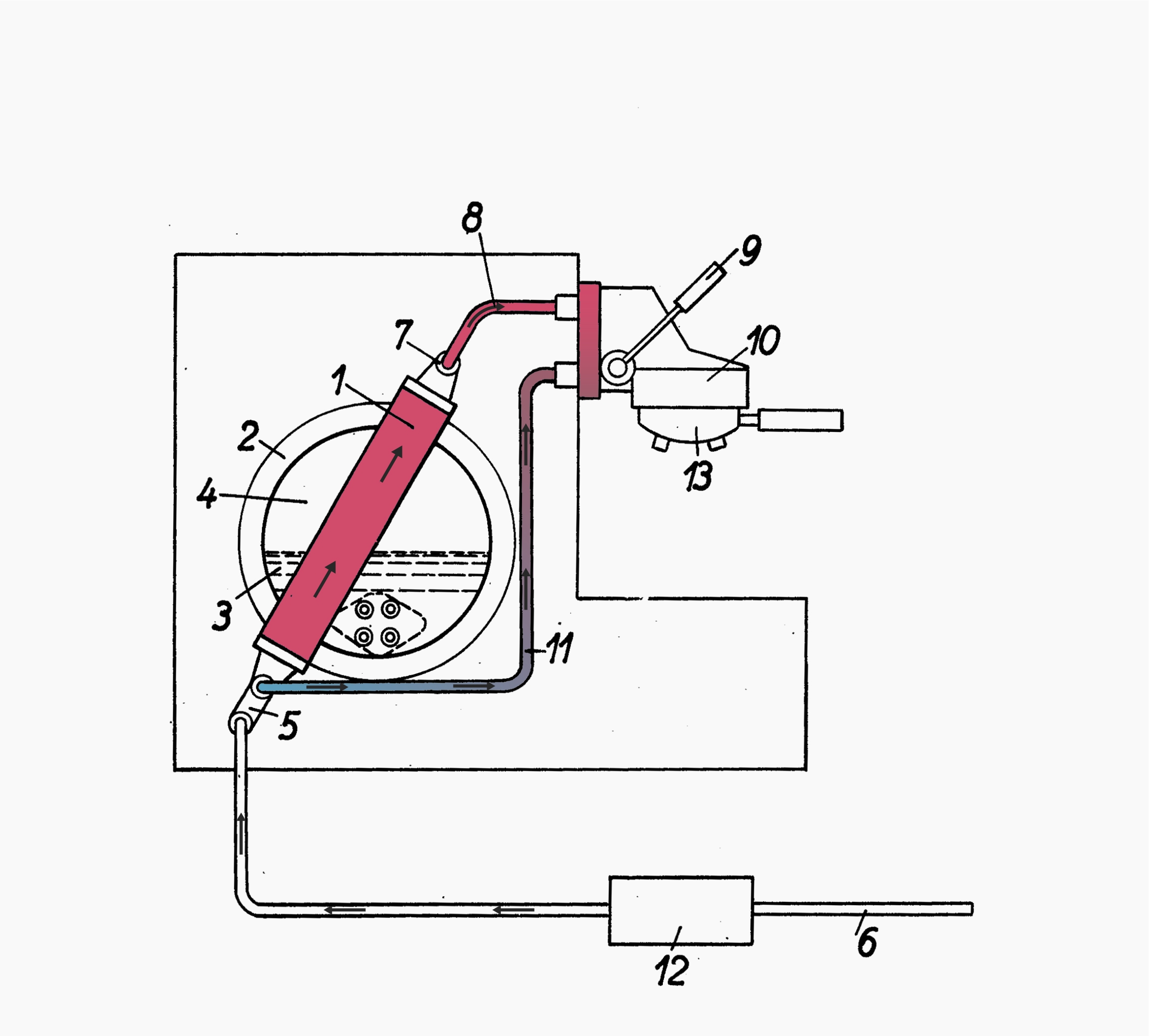

The group head loses heat to the outside air and the water inside it cools down. The cooler water, being more dense, sinks, passing through the lower pipe and returning to the bottom of the heat exchanger. This circular flow constantly supplies hot water to the group head and maintains the temperature of the group head.

When the barista begins to prepare an espresso, fresh, cold water is pumped into the bottom of the heat exchanger and the valve in the group is opened. Water flows towards the group through both sides of the thermosyphon, combining the hotter and cooler waters. The group is made of a large chunk of brass; its big thermal mass stabilises the temperature of the incoming water.

In modern thermosyphon machines, a flow restrictor placed between the heat exchanger and the group (labeled 8 in the diagram below) can help control the temperature in two ways: First, it limits how fast the thermosyphon circulates. This reduces the amount of hot water supplied to the group, making the group cooler when it is not being used.

It also means that when the barista makes an espresso, more water will enter the group from the lower, cooler part of the thermosyphon loop than from the hotter,